Author: Vicki Baker

School/Organization:

Philadelphia High School for Girls

Year: 2018

Seminar: Robots in Healthcare: From Science Fiction to Reality

Grade Level: 9-12

Keywords: algebra, engineering design, linear equations, mathematics, medical robotics, movement, prosthetic, word problems

School Subject(s): Math, Science

This Robots in Healthcare: From Science Fiction to Reality seminar introduced many facets of medial robotics rehabilitative care. This curriculum unit utilizes hands-on explorations of prosthetics and math to create new body part prototypes for medical rehabilitation. The curriculum unit from this seminar will bring real-life mathematics into the classroom and teach students the engineering design process, Students will create a prosthetic finger, hand and lower arm; experiment with different materials and mapping movement using math. The new knowledge that students gain from the lessons will enable them to relate the subject matter to math in new and exciting ways.

Download Unit: 18.05.01.pdf

Did you try this unit in your classroom? Give us your feedback here.

The seminar “Robots in Healthcare: From Science Fiction to Reality” considered robots in the medical field. Many of the topics were science fiction ideas in the past but today are a reality in medical rehabilitation. Whether the task was to replace a missing limb or restore a motor skill lost due to injury or to assist the therapeutic needs of seniors or autistic children, robot designs are inspired by the biology and function of humans and animals. The goal of the seminar was to explore the design and function of robots in medicine and healthcare. It explored how robots work; what animal, human part or function inspired them; how they enhance human function; and how they shed light on human frailties. The activities were designed to show how robot designers use biomimicry to create their robots, how robots sense, think and act on their environment, and how they are being used to advance the healthcare field. Robots are used to increase a human’s power, improve their precision, and extend their capabilities. The seminar incorporated STEM (Science Technology Engineering and Math) knowledge as it relates to the design, evaluation and use of robots in industry. There are many reasons why a curriculum unit focused on robotics and medical robotics would be beneficial to students. Learning engineering and math will increase student interest in attending my school and improving retention of their learning. I am an appointed mathematics teacher at the Philadelphia High School for Girls, a magnet, high school within the School District of Philadelphia. Students apply and are admitted from all Philadelphia neighborhoods and ethnicities of the city having matriculated at private, parochial, magnet, and neighborhood middle schools and charter schools. The Philadelphia High School for Girls has a rich history of academic excellence and a tradition of sisterhood and extra-curricular athletic and scholastic programs. Founded in 1848 to “prepare teachers for the common schools of Philadelphia,” Girls’ High, as it is affectionately known, was the first municipally supported secondary school for girls in the United States and was called the Girls’ Normal School. In 1893, the Philadelphia High School for Girls separated from the Girls’ Normal School, and the foundation for today’s college preparatory curriculum was laid. The school continues to exist as a school for the academically talented, providing young women with outstanding opportunities for scholarship, leadership, and service. Its’ motto, “Vincit qui se vincit” (He conquers who conquers himself), is embodied in the Code of Honor and Courtesy written by students early in this century. (Cutler, 2013). Prior to Central High School, another Philadelphia magnet high school, becoming co-ed, Girls’ High was the only magnet high school for high achieving female students. Today, with more choices for high school matriculation, the programs and experiences we provide effect the students we can attract. Expanding our offerings using medical robotics will make us more attractive to potential students. Robotics and medical robotics will help expand the types of course offerings students encounter: The Philadelphia High School for Girls offers programs which attract students across all grades. In addition to an extensive group of AP courses and a vibrant IB curriculum, the school established a STEM program in the early 2000’s to broaden partnerships with nearby universities and businesses. This program serves as a collection of STEM initiatives championed by Girls’ High mathematics and science teachers. These programs include in-school presentations, summer collegiate opportunities, after school clubs and competitions. The robotics team falls under the STEM umbrella. It is a competition program restarted in September 2016 which allows students to learn engineering principles, computer programming and computer aided design, while building a robot of their own design to meets competition guidelines established yearly by the competition sponsor. The Robots in Healthcare seminar was rich in robotics material and will enhance both my classroom and after school robotics students. Robotics will be woven into my classroom through the curriculum unit and in the robotics team through computer programming, 3-D modeling and enrichment using the Arduino microprocessor. This curriculum unit will bring the knowledge of medical robots to my students. In the unit students will create robots that mimic real life functions. I am fascinated with robotics. Since 2004, I have been involved in after school competition robotics programs. This seminar focusses on a very human issue, robots in medicine and healthcare and provides formal content on engineering design and applying it to real life situations. The unit will teach students the engineering design process, create body replacement parts and use math to determine how it moves. The new knowledge that students gain from the lessons will enable them to relate the subject matter to math in new and exciting ways. Real world investigations help my students see math in everyday situations and relate engineering to biology and the human body. This curriculum unit explores three subjects: the engineering design process in the classroom, the mathematics of robot movement, and medical design: robotic arms, hand and/or fingers. The engineering design process, like the scientific process used in science fair projects, provides the basis for organizing thoughts and design ideas. The mathematics of robot movement provides the link between math and engineering as students explain how and why their creation works. The reflection on medical design relates the real-life application their design achieves. Using math and science together, students will see themselves having fun using math and science increasing the possibility they will seek STEM careers.

This seminar, Robots in Healthcare: From Science Fiction to Reality seminar curriculum unit teaches not only math but also introduces how math is used in engineering to create new parts for medical purposes. Students’ learning experiences will be enriched by engaging in real life engineering work. The unit brings math to light in a real-world sense by considering movement as it relates to robotics. The curriculum unit from this seminar will bring real-life mathematics into the classroom using the medical rehabilitation concept: prosthetics. The importance of authentic educational experiences and STEM education is evident in High school students’ questioning how school and the material they are learning relate to the real world. Math with its abstract reasoning and unique language, seem irrelevant to the future goals of students. Science and math, the language of science, are two subjects with the lowest achievement indicators particularly when measured by standardized tests. These low success indicators effect the number of students pursuing college degrees and careers in Science, Technology, Engineering and Mathematics (STEM). As a nation a new emphasis has been established to increase the number of STEM professionals. This general emphasis also extends aggressively to racial minorities and other under-represented populations in the STEM fields. (Berube, 2014) The Robots in Healthcare: From Science Fiction to Reality” seminar provided an overview of robots in healthcare in three applications areas; assistive devices, rehabilitation technology, and medical devices. These areas were further divided into: Robots Fundamentals: Sensors, Motors, Microprocessors; Robots in education – robot and design toolkits; Robot Inspirations: Humans to Humanoids and Animals to Animaloids; Rehabilitation Robots Areas: prosthetics/orthotics, wheelchairs, technology-mediated exercise, and design for special populations (pediatric and elderly), exoskeletons; Medical Robot Areas: Surgery, Simulation, and Devices (e.g., heart). The focus of this curriculum unit is medical robotics and prosthetics. When society discusses health and healthcare they frequently focus on diet and wellness and their effects on disease and wellness rather than injury and rehabilitation. This is for good reason as non-communicable diseases accounted for 68% of all deaths globally in 2012 and is expected to increase to 73% by 2020. Source: World Health Organization Four Non-communicable Diseases The four main non-communicable diseases, (NCDs), are cardiovascular diseases, cancers, diabetes and chronic lung diseases, contribute to other debilitating conditions for which rehabilitation needs can be high. Debilitating conditions caused by diseases such as stroke (ambulatory issues, speech, quality of life) and amputations due to diabetes, create a need for higher levels of rehabilitative services. The US population, particularly the boomer generation is aging while life expectancy is increasing. Age and the prevalence of disability show a positive correlation therefore as the population ages, their need for assistive devices due to disability also increases. Rehabilitation medicine provides physical medicine and rehabilitation to serve the disabled. Physical medicine provides diagnosis and treatment using medicine, exercise and procedures to treat musculoskeletal disorders while physical therapists, doctors and engineering development provide supports to make the disabled person “maximally able” again. The treatment plan today involves a patient -centered, multi-disciplinary team for treatment. Rehabilitation engineering and medical device design require a personal fit to the patient and the places they live work and play. It relies on the social and political regulations and can be successful when all stakeholders work together. People needing rehabilitation are classified in five target groups: traumatic injuries (amputation/limb loss, brain injury (due to falls, motor vehicle accident etc.), and spinal cord injury); non-traumatic injuries sustained from cardio-vascular disease and cardio-vascular accidents (strokes); pediatric injuries and diseases such as vertebral palsy and autism; degenerative diseases such as multiple sclerosis and Parkinson’s disease; and diseases from aging such as dementia and Alzheimer’s disease. The rehabilitation needs, and the millions of dollars needed to create the supports create fertile ground for medical rehabilitative and robotic devices. Robotic devices such as that interact with patients as well as those that assist patients or even replace missing limbs are all used to make life better for those in need. Prosthetics whether simple or robotic are defined as artificial devices used to replace a missing body part, such as a limb. It must attach to an existing human stump of shoulder, must be light weight and will perform a function that the patient cannot accomplish without assistance. (Wikipedia, 2013). Bodily needs that can ultimately result in needs for prosthetics range in diagnosis to include upper extremity and lower extremity diagnoses. Upper extremity diagnoses include the hand through complete the arm and the upper body. The cause of the diagnosis can be fractures, dislocations, crush injuries, joint replacements, over use injuries such as trigger fingers, tendon and/or ligament tears/repairs, pain, nerve and neuropathies, arthritis and rheumatic diseases and congenital anomalies. Assessment of upper extremity diagnoses can include occupational therapy, physical therapy, rehabilitation (message, stretching) physical agent modalities (wax treatments, ultrasound), isolation of upper body therapies, and activities to strengthen the ability to perform daily living activities. Physical remedies can also include splints and orthoses. Lower body diagnoses include the lower extremity of the body from the hip through the feet including the toes. The cause of the diagnoses is the same as upper extremities and can be fractures, dislocations, crush injuries, joint replacements, overuse injuries such as trigger fingers, tendon and/or ligament tears/repairs, pain, nerve and neuropathies, arthritis and rheumatic diseases and congenital anomalies. Assessment and treatment of lower extremity diagnoses typically fall in the physical therapy domain and include a treatment program of strengthening on treadmills, stairs, exercises for gait and stride, motor coordination, balance and paresis. Lower Extremity solutions are very complex. Walking is a very complex event involving the coordination of center of gravity (balance), vision, soles of the feet, weight, gait and ankle movement. As the diagram below shows forward progression involves many factors. Walking forward The public frequently calls the loss of a limb by cutting amputation. In the medical profession amputation has a very specific definition. Cutting of an extremity whether whole or partial, through the bone is an amputation. Cutting the extremity in whole or part through the joint is considered disarticulation. There are many reasons for amputations: vascular disease, malignant tumors, trauma, congenital. The most common is peripheral vascular disease (90%) while congenital is the lowest (3%). The location of amputations is very strategic. Efforts are made to leave a lever whether upper or lower for increased movement and ability to accomplish normal tasks. When amputations are necessary, the replacement with a prosthetic is customized for the patient. For the artificial limb to fit precise measurements are taken, the weight and size are calculated to be consistent with the patient. Prostheses designers consider ease of use and the degrees of freedom which is important for accomplishing everyday tasks. There are almost five million amputees in the United State and Europe alone. (Raspopovic, 2016). The introduction of robotic protheses has improved the quality of life for many patients. These newer devices such as the 6-DOF prosthetic arm increase the degrees of freedom, are sophisticated enough to do some of the lifting and rotating of extremities such as the wrist. Disadvantages are primarily weight since the new features increase the weight and resulting in fewer hours a person can wear it. Some patients have multiple prostheses each dedicated to tasks or situations: one aesthetic and one functional (Piazza, 2017). New areas of prothesis research include technology allowing sensory feedback (touch, temperature and pressure), special sensors to power joints and provide movement and muscle reinnervation, (surgical procedures to redirect amputated nerves to healthy muscle) (Ahmadizadeh, 2017). Wearable exoskeleton also provides better materials for movement for lower extremity prostheses (Garate, 2016). Upper-limb prosthetics technology such as the reverb arm (partial hand technology) and i-LIMB fully articulating prosthetic hand give hope to patients for better products to meet their needs. (Fairley, 2009). Innovative prosthetic hand designs are rare given they lower demand versus lower extremities ((Cipriani, 2011). New prosthetic designs are created by engineers using the engineering design process. This prescribed process is a series of steps that guides engineering teams as they solve problems. The design process is iterative, meaning that the steps are repeated as many times as needed, making improvements along the way as we learn from failure and uncover new design possibilities to arrive at great solutions.Robotics in Healthcare

Non-Communicable Diseases (NCDs)

· The four main NCDs are cardiovascular diseases, cancers, diabetes and chronic lung diseases.

· Communicable, maternal, neonatal and nutritional conditions collectively were responsible for 23% of global deaths and injuries caused 9% of all deaths.

Rehabilitation Classifications

Prosthetics

Body relationships:

Walking forward requires interaction of selective postures, muscular force and tendon elasticity. Once a person begins to walk forward the foot must pivot to provide forward movement and balance.

Amputations

Customizing Prostheses

Robotics Devices

The Engineering Design Process

Objectives: Students will be able to apply math that they learn in class to relate math to real world problems. This unit will emphasize the importance of education across both science and math as a vehicle to improve STEM knowledge using a cross curricular approach involving science and math. Strategies: Ultimate transfer desired: Students will be able to apply mathematical knowledge, skill and reasoning to solve real life problems concerning kinematics related to prosthetics and medical technology.

Lesson Plan Desired result:

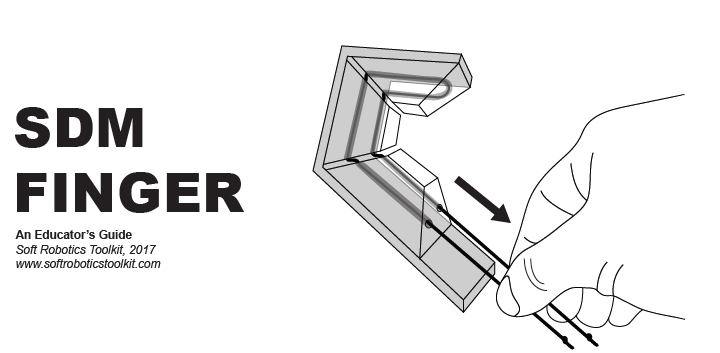

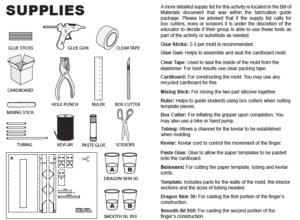

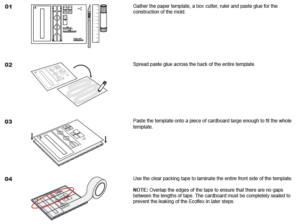

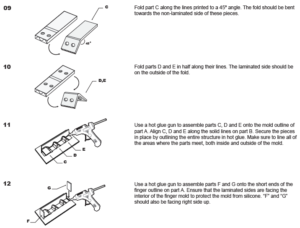

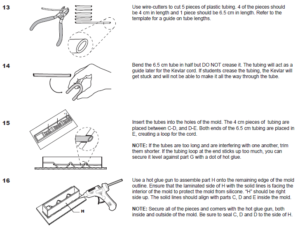

Lesson Objectives Students will create soft robot finger prostheses using molds; Students will us soft finger prosthesis to model linear equations; Students will write story graphs consistent with their liner model and their own imagination Pacing Day 1, 45 minutes Creating mold (steps 1-8) Day 2, 45 minutes Finishing the mole (steps 9-16) Day 3, 45 minutes Making the finger (steps 17-20) Day 4, 20 45 minutes Removing finger, creating the model (step 21-23) Day 5, 45 minutes Group reports Essential Learning Objectives Part 1: Students will have experience making a mold and dividing the mold into subsections to create the sections that give the finger the ability to move. Students will create a two-part cast by pouring and curing two different materials into the same mold to achieve a specific prosthetic finger that moves. Part 2: Using the finger they have created students will count the number of bends their finger makes in one to 2 minutes. Based on this data they will create a chart, graph and write the mathematical model for the relationships. Previous Learning: Students have prior knowledge of (x,y) coordinates, slope (rate of change) inverse operations Soft Robotics Materials for teacher: (See appendix for buying guide) Materials for students: Silicone elastomer, Kevlar cord, Cardboard, Hot glue, hot glue, gun, Tubing Introduction (5 minutes): Have students find the equation of a line using two points and create a scenario for their answer (a story) and a graph. Exploration: SDM Finger Fabrication Guide (40 minutes per day for 4 days) Closure (as time permits): Writing prompt to write the equation of a line I… Homework: Write the equation of a line given 2 points; write a story and graph the line. The following instructions are available for public use from An Educators Guide, Soft Robotics Toolkit 2017, www.softroboticstoolkit.com Lesson Objectives To create a lower extremity prosthetic and model its articulation in x-y and x-y-z space. Pacing Day 1, 45 minutes Measuring and creating the form Day 2, 45 minutes Finishing the arm; graphing in 2 and 3 D Day 3, 45 minutes Group reports Essential Learning Objectives: Students will have experience making an upper extremity prosthetic lower arm from any material they desire. Previous Learning: Students have prior knowledge with angles in the x-y coordinate system; students have explored prothesis and understand the degrees of freedom, limitations/issues based on where a limb is attached Materials for teacher: Tag board of different colors (for students without materials) Materials for students: Tag/poster board (material of their choice), tape, graph paper; chart paper (groups will report out 1 design; each student will have their own design) Introduction: (5 minutes) What is the ideal lower arm length? How do you define ideal? Exploration: In groups of 2 -4, using your “ideal” arm length, create a lower arm prosthesis. Where will your arm attach (i.e. what is the nature of your “stump”). For your situation, map out the motion in x-y space and x-y-z space that your arm can accomplish. What is your quality of life? Should you modify your design? IF so, what would you change? Closure: (as time permits) Exit ticket – You are the Inquirer reporter who visited our class today write a short review Homework: You design is a big hit. Design fabric covers for your arm. How much fabric will you need if each arm in of identical size to our prototype? Select the fabric you would like and (find a fabric store on line print off your selection). Describe the cost and your design. Overall Objective To create hand prosthetic and model its articulation in a case at an arcade. Using the lower arm prosthetic how will you attach the hand to reach into the glass case and get a prize. Pacing Day 1, 45 minutes Understanding the problem; brainstorming Day 2, 45 minutes Finishing the mole (steps 9-16) Day 3, 45 minutes Making the finger (steps 17-20) Day 4, 20 minutes Removing finger, creating the model (step 21-23) Day 5, 45 minutes Group reports Essential Learning Objectives: Students will make a hand prosthetic using the engineering design process. Previous Learning: Students created a fictitious cellphone case suing the engineering design process. They can work effectively in groups. Materials for teacher: See materials list in Appendix Materials for students: Thick rubber bands, jumbo wooden craft sticks, industrial strength duct tape, flexible straws, cardboard, Playtex glove tips, thick string, hot glue, scissors, ruler. Engineering design process list and report paper Introductions: (5 minutes) Describe how your hand is designed. How does it work? Exploration: In groups of 2 -4 students design a prosthetic hand using the materials given. You do not have to use all the materials, but you may not add any. After you build the hand it hand will have to reach inside a box and pick up arcade toys. Describe the function the motion the hand makes from the top of the box to the toys. Closure: (as time permits) Did you have enough material? Why or why not? Homework: Find pictures of real life prosthetic handsLesson 1: Soft Robotics – Finger Movement Story

Lesson 2: Designing a Lower Extremity Prosthetic

Lesson 3 The Hand Knows – Designing a prosthetic hand to pick up arcade toys (modeling quadratic motion)

[Please see PDF attached above for appendices]

Ahmadizadeh, Chakaveh, et al. “Toward Intuitive Prosthetic Control: Solving Common Issues Using Force Myography, Surface Electromyography, and Pattern Recognition in a Pilot Case Study.” IEEE Robotics & Automation Magazine, vol. 24, no. 4, 2017, pp. 102–111., doi:10.1109/mra.2017.2747899. Berube, Clair T. STEM and the City: A Report on STEM Education in the Great American Urban Public-School System. Information Age Publishing, Inc, 2014. Brown, Alan S. “Face to Face with Autism.” Mechanical Engineering, 2018, pp. 35–39. Cipriani, Christian, et al. “The SmartHand Transradial Prosthesis.” Journal of NeuroEngineering and Rehabilitation, vol. 8, no. 1, 2011, p. 29., doi:10.1186/1743-0003-8-29. Cutler, William V. “Encyclopedia of Greater Philadelphia.” Choice Reviews Online, vol. 51, no. 01, 2013, doi:10.5860/choice.51-0003. A short history of Philadelphia and its education institutions Fairley, Miki. “State-of-the-Art: Upper-Limb Prosthetics Technology.” The O&P Edge, Oct. 2009, opedge.com/Articles/ViewArticle/2009-10_01. Science fiction is meeting real life and scientific breakthroughs in prosthetics in clinical practice. This article discusses upper-limb technologies which will improve the quality of life for many amputees. Garate, Virginia Ruiz, et al. “Walking Assistance Using Artificial Primitives: A Novel Bioinspired Framework Using Motor Primitives for Locomotion Assistance Through a Wearable Cooperative Exoskeleton.” IEEE Robotics & Automation Magazine, vol. 23, no. 1, 2016, pp. 83–95., doi:10.1109/mra.2015.2510778. Holland, Donal Padraic, et al. “The Soft Robotics Toolkit: Strategies for Overcoming Obstacles to the Wide Dissemination of Soft-Robotic Hardware.” IEEE Robotics & Automation Magazine, vol. 24, no. 1, 2017, pp. 57–64., doi:10.1109/mra.2016.2639067. Iosa, Marco, et al. “The Three Laws of Neurorobotics: A Review on What Neurorehabilitation Robots Should Do for Patients and Clinicians.” Journal of Medical and Biological Engineering, vol. 36, no. 1, 2016, pp. 1–11., doi:10.1007/s40846-016-0115-2. Laschi, C., and B. Mazzolai. “Lessons from Animals and Plants: The Symbiosis of Morphological Computation and Soft Robotics.” IEEE Robotics & Automation Magazine, vol. 23, no. 3, 2016, pp. 107–114., doi:10.1109/mra.2016.2582726. Nocks, Lisa. “500 Years of Humanoid Robots Automata Have Been Around Longer than You Think [Resources_Review].” IEEE Spectrum, vol. 54, no. 10, 2017, pp. 18–19., doi:10.1109/mspec.2017.8048830. Piazza, C., et al. “The SoftHand Pro-H: A Hybrid Body-Controlled, Electrically Powered Hand Prosthesis for Daily Living and Working.” IEEE Robotics & Automation Magazine, vol. 24, no. 4, 2017, pp. 87–101., doi:10.1109/mra.2017.2751662. Raspopovic, Stanisa, et al. “Regaining Feeling from Lost Limbs [Industrial Activities].” IEEE Robotics & Automation Magazine, vol. 23, no. 1, 2016, pp. 13–14., doi:10.1109/mra.2015.2511685. Tadesse, Yonas, et al. “Musculoskeletal System for Bio-Inspired Robotic Systems.” Mechanical Engineering, vol. 138, no. 03, 2016, doi:10.1115/1.2016-mar-8. Verner, Igor M., et al. “Science Class with RoboThespian: Using a Robot Teacher to Make Science Fun and Engage Students.” IEEE Robotics & Automation Magazine, vol. 23, no. 2, 2016, pp. 74–80., doi:10.1109/mra.2016.2515018. Zanchettin, Andrea Maria, et al. “Achieving Humanlike Motion: Resolving Redundancy for Anthropomorphic Industrial Manipulators.” IEEE Robotics & Automation Magazine, vol. 20, no. 4, 2013, pp. 131–138., doi:10.1109/mra.2013.2283650